Food waste management from commercial operations

As an alternative to landfill, solid waste materials that are generated from commercial operations such as catering kitchens, fruit & vegetable outlets, food halls and the like can be recovered or repurposed through dehydration, dewatering and digestion processes.

A common means of processing this commercial food waste is by the use of food waste management machines.

Depending upon the type of machine used there will be solid organic material left over within the machine after processing (which is then recycled as mulch or compost for agricultural or landscaping purposes) or the solids are transformed into a liquid trade waste.

Note that food macerators (food waste disposal units - FWDs) are prohibited fixtures and must not be connected to our sewer system.

Types of food waste management machines

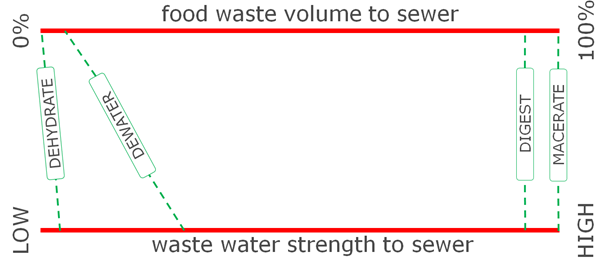

Food waste management machines can be generally classified according to the following processes being applied:

- Dehydrate - 100% solids removal from machine at end of cycle. Reasonably clean water condensate discharged to sewer.

- Dewater - Near 100% solids removal from machine at end of cycle. Reasonably to moderately clean dewater discharged to sewer.

- Digest - Significant proportion of waste is transformed into a high strength wastewater that is discharged to sewer via pre-treatment apparatus.

- Macerators - 100% solids enters sewer after every use. Macerators are prohibited fixtures and must not be connected onto the Corporation’s sewer system.

Installation & use of food waste management machines

Installation of a specific food waste management machine will require the business owner or property owner / manager who operates the food waste management machine to apply for a trade waste permit before any discharge approval is considered.

Food waste management machines that require direct water connections must have appropriate backflow prevention installed as per the latest version of AS/NZS 3500.1.

Maintenance of food waste management machines must be undertaken in accordance with manufacturer’s guidelines.

If the trade waste discharged from food waste management machines breach the trade waste permit approval it may result in legal action pursuant to the Water Services Act 2012 and / or the specific food waste management machine being deemed a prohibited fixture and required to be disconnected from our sewer system.

Trade waste permit applications must be submitted to tradewaste@watercorporation.com.au.

New food waste management machine installations

Depending upon the type of food waste management machine to be installed then the following shall also apply for all commercial food waste management installations:

Dehydrate

- May be required to operate under a new or amended trade waste permit.

- No trade waste charges shall apply for the waste exiting the food waste management machine.

Dewater

- Will be required to operate under a new or amended trade waste permit.

- Trade waste usage charges may apply for the volume and quality of the waste exiting the food waste management machine.

- May be requested to be connected to a suitable form of trade waste pre-treatment.

Digest

- Will be required to operate under a new or amended trade waste permit.

- Must have a dedicated grease / solids arrestor installation with no additional waste streams (i.e. cannot be a shared grease / solids arrestor with other business waste streams).

- The dedicated grease / solids arrestor size will be determined by Water Corporation.

- The waste stream entering the dedicated grease / solids arrestor must not be via any form of direct pumped means. Holding tanks can be used downstream from a pumping mechanism. No other waste streams can enter the holding tank. Flows must enter the dedicated grease / solids arrestor naturally at the machine’s designed output and not at any higher flow rate. Instantaneous dumps of collected machine waste from a holding tank is not permitted. Please e-mail tradewaste@watercorporation.com.au for any installation queries.

- The dedicated grease / solids arrestor pump-out regime will be set at a particular frequency based upon the size of the arrestor and machine to be installed.

- The compliance with the grease / solids arrestor pumpout regime will be monitored as part of the Water Corporation’s FOGMan program. This will incur a FOGman charge.

- Should the business owner seek to review the pump out regime then a grease arrestor pump-out frequency reassessment can be requested. This will incur a pump-out frequency reassessment charge.